Introduction of LXML Sepon

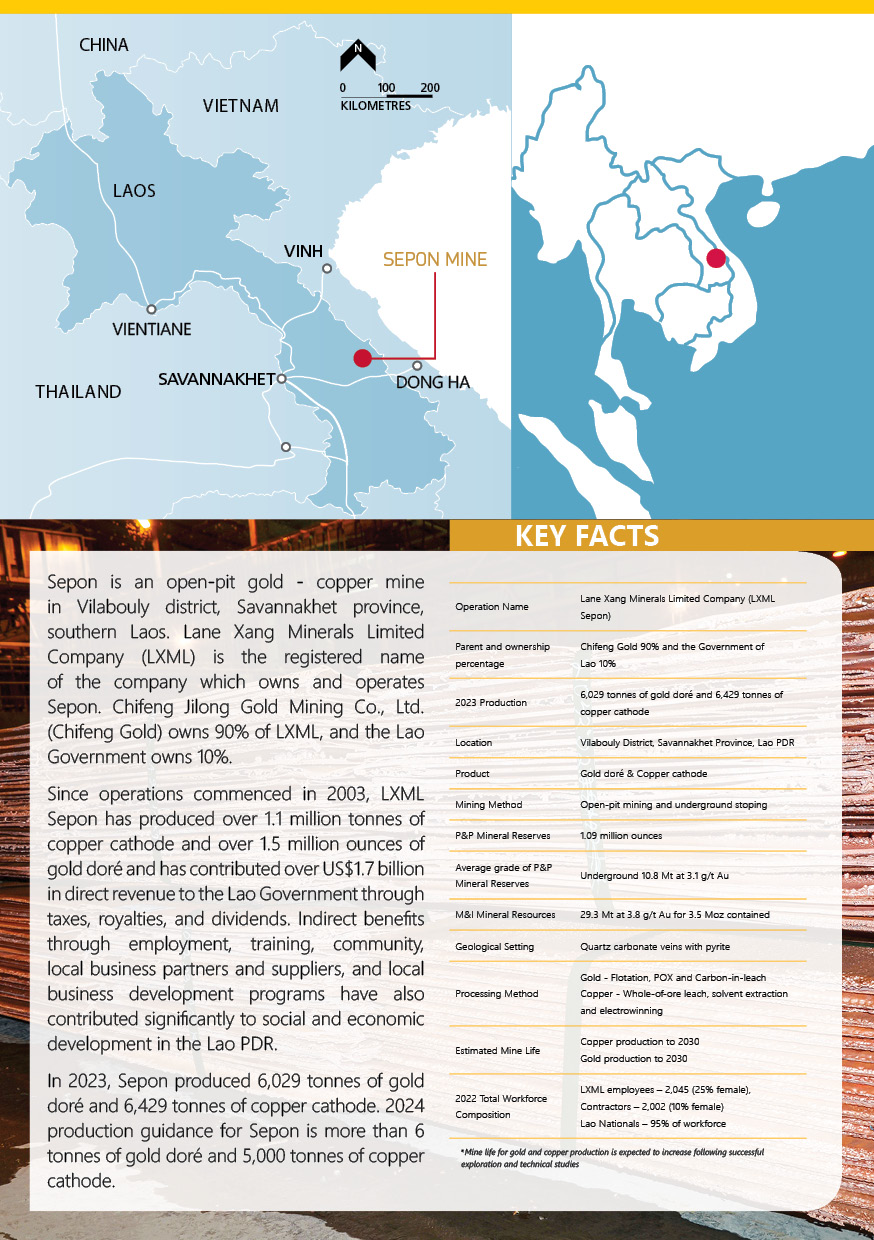

Lane Xang Minerals Limited Company (LXML Sepon) operates the Sepon Gold and Copper Operation located in Vilabouly District, Savannakhet Province, Lao PDR.

Lane Xang Minerals Limited Company is the registered name in Laos in which Chifeng Jilong Gold Mining Co., Ltd (Chifeng) owns 90% and the Lao Government owns 10%.

Since the operations commenced in 2003, Sepon has produced over 1.1 million tonnes of copper cathode and over 1.5 million ounces of Gold doré.

In 2023, Sepon produced 6,500 tonnes of copper and 6 tonnes of gold. Planned production for 2024 is over 6,2 tonnes of gold and 5,305 tonnes of copper cathode.

Major Shareholders

The Lao Government owns 10% of LXML. Chifeng Jilong Gold Mining (Chifeng) owns 90% of LXML.

Chifeng Gold is a Shanghai stock exchange-listed metals producer (SH:600988).

Chifeng Gold owns 7 operating mines and 1 comprehensive resource recycling company in China, Southeast Asia and West Africa, including Jilong Mining - Zhuanshanzi Gold Mine, Wulong Mining - Wulong Gold, Huatai Mining - Honghuagou Gold Mine, Jintai Mining - Xidengping Gold Mine, Hanfeng Mining - Tianbaoshan Zinc-Lead-Copper-Molybdenum Polymetallic Mine in China, Sepon Au-Cu Mine in Laos, Golden Star Wassa Gold Mine in Ghana. The comprehensive resource recycling project is a disassembly business of waste electrical and electronic products conducted by Guangyuan Technology in Hefei, Anhui Province, China.

The company is seeking to acquire more high-quality gold projects to expand into a mid-tier international mining company.

Introduction of LXML Sepon

Chifeng LXML Sepon Commence gold Processing

LXML Sepon History

Underground Exploration

Sepon mine to operate the first modern underground mine in Lao PDR.

With a mineral resource of 9.5 million tonnes and projected ore production to increase from 400,000 tonnes in 2023 to 1.2 million tonnes per annum thereafter, the “Discovery Deeps Underground Mine” is expected to extend Sepon’s mine life for at least another seven years, to 2030, contributing to poverty reduction and sustainable development in host communities.

The underground mine will extend 450 metres below the surface. The decline access tunnel will be more than 1,800m long, 5m high and 5m wide to accommodate modern underground excavation and drilling equipment

Gold Production

Since gold production commenced in 2003, Sepon produced over 1.5 million ounces of gold dore. Gold production ceased in 2013 due to price and other factors. In June 2020, Sepon recommenced gold production, marking the beginning of a New Gold Era for Sepon mine under Chifeng Gold.

Sepon invested in new facilities and equipment, including a flotation plant, oxygen plant, and an elution and carbon regeneration plant to process primary gold ore and improve recovery. This significant investment is expected to extend Sepon’s mine life for at least ten years.

Copper Production

Since copper production commenced in 2005, Sepon produced over 1.1 million tonnes of copper cathode. Sepon produces copper cathode using a whole-of-ore leach, sovent extract and electrowinning (SX-EW) process. Copper Cathodes are then transported via road and sea to manufacturers of cable, wire and tube in Asia.

Our copper production also uses a Heap Leach solution that will allow Sepon to process the significant low-grade primary copper resource that would otherwise be uneconomical to process.

Heap Leach Pilot Program

In mid-August, we commissioned our Pilot Heap Leach Facility, another project under budget and on time, and another significant milestone for LXML. This Pilot Heap Leach Facility is a first for Sepon and is part of our study into the potential for continuing copper production after our transition to gold production. Heap leach is a lower cost method that will allow Sepon to process the significant low-grade primary copper resource that would otherwise be uneconomical to process.

The heap leach pilot facility has a total capacity of 900,000 tonnes and is set to operate as a dynamic pad for 18 to 24 months. Currently, 400,000 tonnes of ore will contribute 3,000 copper tonnes.